VDL Groep and Airbus are joining forces on laser communication terminals for aircraft

Airbus and VDL Groep will be cooperating on the development and production of laser communication terminals for aircraft, called UltraAir. Work will commence with the development and production of a prototype. An initial test flight is planned for 2024. This will build on the developments initiated by aerospace company Airbus and research organisation TNO.

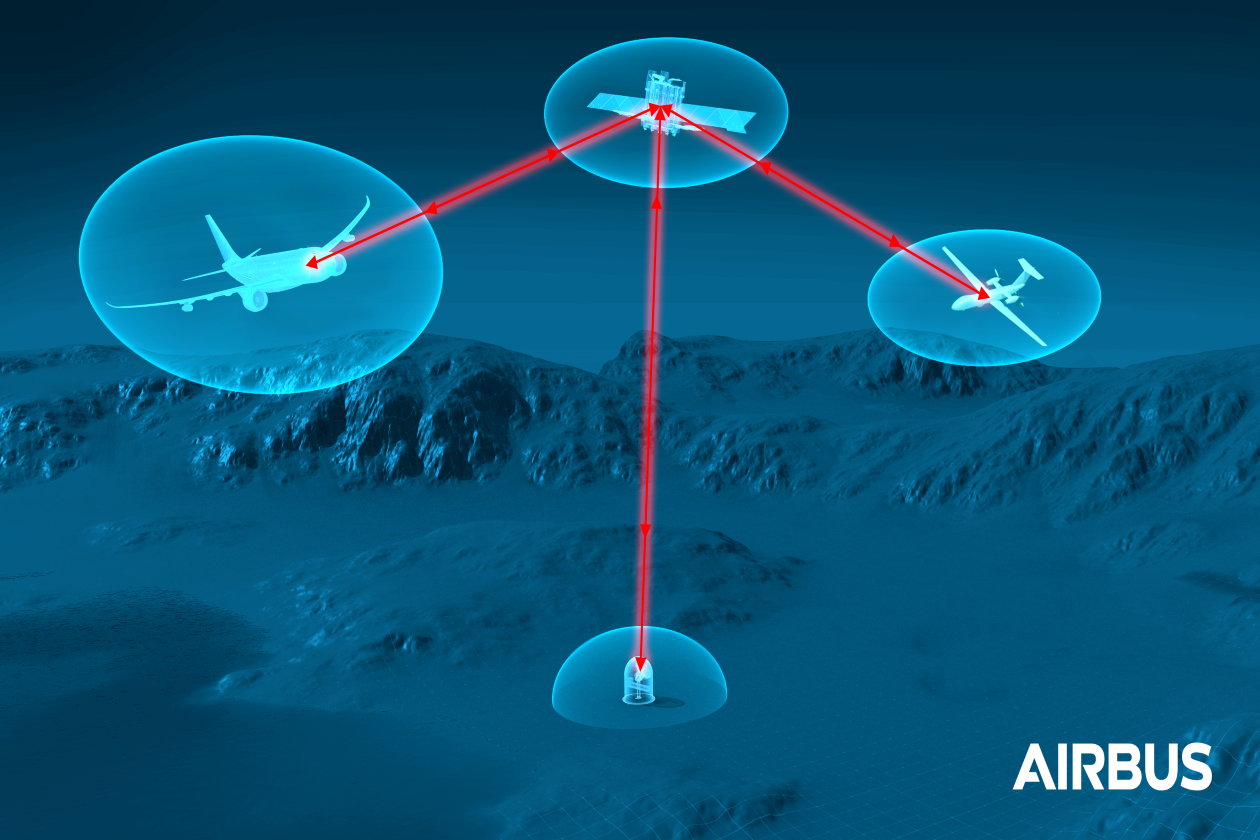

UltraAir equipment allows large amounts of data to be exchanged via laser links in a network of ground stations and satellites orbiting 36,000 kilometres above the earth. Using advanced technology, including a highly stable and accurate optical mechatronic system, laser communication terminals allow transmission speeds of gigabits per second to be achieved, while also preventing interference and obtaining a low probability of interception.

Connections

With that UltraAir will allow military aircraft and unmanned aerial vehicles to connect with a multi-domain combat cloud by using laser-based satellite constellations, such as the SpaceDataHighway network from Airbus. This is a key milestone in the roadmap of Airbus’ overall strategy to drive laser communication further, which will bring forward the benefits of this technology as a key differentiator for providing multi-domain combat cooperation for government and defence customers. In the longer term, UltraAir could also be implemented on commercial aircraft to allow airline passengers to establish high-speed data connections.

Next revolution

Laser communication technology represents the next revolution in satellite communications (satcom) as a solution to data traffic in the quantum age. The growing demand for satellite services means that the capacity limits of traditional radio frequencies for satellite communication are being reached. However, laser satellite communication will make it possible to process a thousand times more data, faster by a factor of 10 as compared to the current network. Laser links also offer the advantage of low levels of interference and potential detection. Unlike the already congested radio frequencies, laser communications are difficult to intercept as the beam is narrower. This makes laser terminals lighter and more compact, consuming less energy and providing greater security than radio links.

The collaboration between Airbus and VDL includes the development of a demonstration model and prototype for UltraAir, as well as the necessary further steps required to produce UltraAir in volume. VDL ETG Almelo will handle production as well as supply critical systems, among other activities. Airbus will then market UltraAir.

Added value

“As a high-tech supplier and partner for companies in the semiconductor industry in particular, we see a lot of added value in taking on the challenges of this project for Airbus,” explains VDL ETG Almelo Managing Director Sander Verschoor. “So that these complex terminals, which will be equipped with mirrors and motors, as well as mechatronics and optics among other features, can be produced in volume, we will be closely involved in the development of the technology from the outset. For example, we will be applying our system architecture and design competences here. Needless to say, we will be working intensely with other partners such as Demcon and TNO during this process.”

Investments

Airbus and VDL Groep will undertake further steps in 2024 in order to industrialise the prototype with the aim of making the laser communication terminal ready for integration with an aircraft. A test flight of the industrialised prototype on an aircraft is planned for 2025. The development of UltraAir has been made possible through investments from Airbus and VDL Groep and is supported by the ESA ScyLight (Secure and Laser Communication Technology) programme and by the allocation of the Dutch National Growth Fund NxtGen Hightech proposal, led by TNO and a group of Dutch companies.