Select language

About

VDL ETG SWITZERLAND AG

VDL ETG SWITZERLAND AG

HIGH-TECH SYSTEM INTEGRATION WITH SWISS PRECISION

Located in Trübbach, VDL ETG Switzerland AG specializes in the system integration of mechatronic (sub)systems for OEMs in the high-tech capital goods sector. With over 75 years of experience, we bring crutual expertise to projects requiring the highest precision and reliability. As a full-service system supplier, we support our customers from (co-)design through to production including all relevant production steps such as cleaning, RGA qualification, cleanroom assembly, and functional testing of complete Systems.

Driven by a passion for innovation, precision, and engineering excellence, these values are deeply embedded in our DNA. As a multi-ISO-certified company, VDL ETG Switzerland meets the most stringent industry standards, ensuring quality and performance in every detail.

TECHNOLOGICAL EXPERTISE FOR

DEMANDING INDUSTRIES

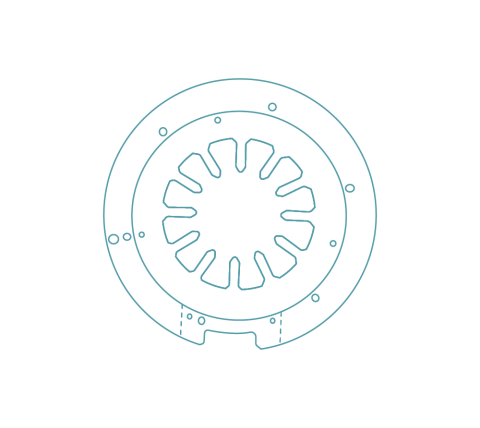

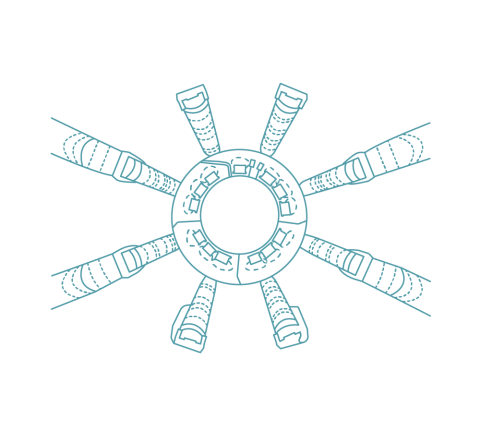

We are your trusted partner in the development and manufacturing of vacuum components, coating systems, and mechatronic assemblies for technically demanding industries. Our solutions meet the highest standards in precision, quality, and functionality, and are used worldwide across high-tech sectors such as semiconductors, analytics, optics, and medical technology. From the initial concept to series production, we support our customers with engineering expertise, advanced manufacturing optimization, and a strong commitment to quality and on-time delivery.

- Coating systems for tools, functional surfaces, and industrial applications.

- Mechatronic modules, delivered as ready-to-install, tested, and fully functional units.

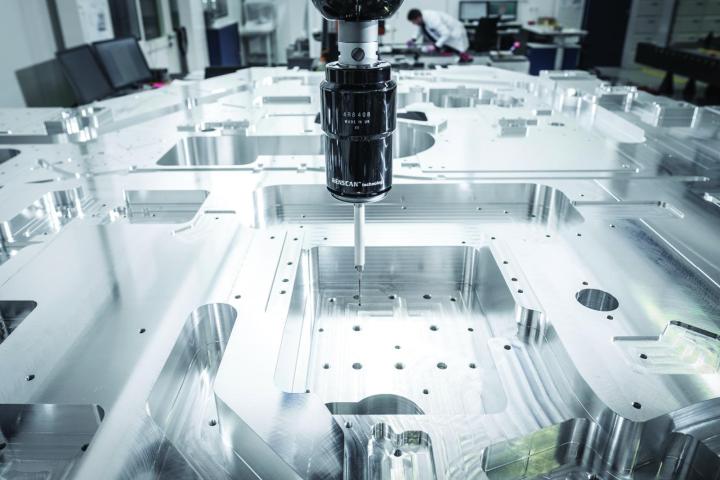

- Large-part machining, with CNC processing of components up to 4 meters using state-of-the-art equipment.

CORE COMPETENCES

Milling and turning

Measuring technology and qualification

Welding

Cleaning

Vacuum Brazing

Clean room and grey room assembly

ADVANCED MACHINE PARK

With our advanced and versatile machine park, we are equipped to meet nearly any customer requirement - from precision turning and milling to the production of both small components and large-scale parts. Our capabilities span a wide range of dimensions and complexities, allowing us to support diverse industries with tailored machining solutions. Interested in discovering more about VDL ETG Switzerland’s machine park? Download the brochure below to explore our full range of equipment and expertise.

VDL ETG Switzerland

Tel: +41 (0)81 784 64 00

Sales and Marketing

New Business Development